Delmec has been involved in tower builds for almost fifty years, across multiple countries and continents. In that time, we’ve seen major variances emerge in the availability and quality of one key ingredient — concrete.

Here in Europe, ready-mix concrete (RMC) is always available for telecom foundation construction projects. However, in the African market, where we carry out a large number of site services, the situation is different. There, ready-mix concrete is available around 70% of the time in some urban areas but may only be used around 10% of the time. That’s due to constant fluctuations in price: for example, ready-mix concrete costs approximately $190/m3, while site mixed is $140/m3. The average foundation may use 30m3 of concrete, so that represents a potential $1500 difference.

For this reason, the concrete is usually mixed on site, often in batches of 100l – 400l, running two cement mixers concurrently. The challenge with this method is that it can lead to problems with concrete hardness and quality.

Failing foundations

During the quality assurance (QA) phase of new tower builds, the concrete may fail to meet the required design standards, which is typically 25MPa. Research into the cause of concrete QA failures revealed the following factors: cement age and storage; cement grade; gravel quality; water quality; curing practices; and subcontracting.

Delmec has been carrying out root cause analysis in this area and is actively addressing these issues with technical bulletins, toolbox talks and discussions with clients and contractors. In this post, we’re sharing some highlights from our findings.

- Cement age & storage

In fast-moving, well-connected markets, cement age and storage isn’t a huge concern. However, in parts of Africa where logistic challenges persist, delays may cause serious problems because after three months, cement absorbs moisture and can lose up to 20% of its strength. For example, in countries such as The Democratic Republic of the Congo (DRC), cement is often purchased from Uganda and Rwanda, which generates a lead time of as much as two to four weeks in remote areas.

This means that concrete may suffer a significant reduction in strength while in transit, and even more if it’s held in customs or on site for long periods of time. The below table shows how ageing may affect the material:

- Cement grade

We’ve found that a common feature for foundations with low compressive strength failures is the use of 32.5R grade cement. We always recommend the use of 42.5R grade for site mixes in Africa to overcome the issues of cement age, humidity, degradation, water quality, curing, etc.

While access to higher grades may be a challenge, it’s one we should all strive to overcome as our analysis reveals that this is one of the primary causes for problematic foundation conditions.

- Cement curing

Regional experts such as Delmec know that in African environments, concrete should be watered until initial touch hardness is achieved. Then sacks should be placed on the concrete and watered regularly for up to 4-5 days.

Through our research into QA-failed sites, we’ve found that in some cases, soil backfilling and compaction was taking place after three days. This will not allow the concrete to adequately hydrate and harden.

- Quality control

Another important cause of concrete QA failures is quality control, particularly around subcontracting. Delmec trains both their clients and tier-two contractors in industry-leading quality control processes which, when followed correctly, result in successful QA.

However, this control can be compromised if the tier-two contractor passes the work to a tier-three contractor. Subsequently, the contractors working on site may be inexperienced in quality control, using incorrect cement mix ratios, curing times, etc. This can lead to serious faults in the foundations, which have to be rectified at great expense.

Costly solutions

Any or all of the above factors and failures can be costly, as evidenced by one particular situation we encountered in the African market.

In this instance, the foundation for a new tower was constructed with 33m3 of concrete at a cost of $23,000. A subsequent quality assurance inspection found the concrete to be of very poor quality. This triggered additional investigations which involved an independent university carrying out core sampling and crush tests. Their findings revealed concrete strengths of 4MPa — roughly equivalent to ice.

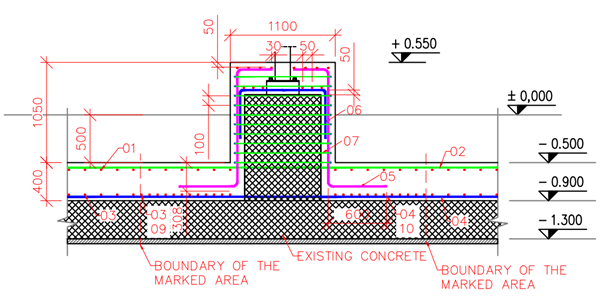

The solution to fix the endangered foundation was to assume the concrete was similar to soil or concrete blinding. This meant that the team then had cast a new concrete foundation on top of the existing foundation slab, followed by jacketing of the columns. In this case, the cost of the investigations and foundation enhancements came to approximately $32,000, more than doubling the initial price of this phase of the project.

Invaluable expertise

This proves that in the towerco industry, as in most fields, it pays to do the job right the first time. In every location Delmec operates in — whether it’s Poland or Pakistan — we know there will be individual challenges to overcome. Our clients and customers rely on our vast experience, deep local knowledge and up-to-date expertise to make sure that costly mistakes are avoided. While we can and do supply problem-fixing solutions, it’s best to engage companies like Delmec in the early stages of a project.

By working together to improve on-site skills, smooth logistical routes and tighten up on quality control, we can ensure our colleagues and communities enjoy safe, functional and connectivity-enhancing facilities.

If you’re interested in learning more about our research in this area, contact us for information on our technical updates, toolbox talks and ongoing speaking events.

">

"> ">

"> ">

">