As a truly global company, Delmec operates in a variety of territories, countries and continents. That means that our team is experienced in adapting for different governance models so that our services are up-to-date and compliant in every sphere of operation. One such varying standard are design codes, which are essential for ensuring that our clients’ structures meet national regulations.

A Brief History of Design Codes

Not every location has an established design code, but if there is one in place, our engineers are obligated to design structures in accordance with the code’s parameters. They’re usually drafted by a governing body and generally represent a best-practice approach to help prevent accident and injury as a result of poor design standards. At Delmec, the three design codes we encounter most regularly are the TIA code, British Standard and Eurocode. For the African market we use the TIA code, for Ireland and the UK the British Standard, and for the rest of Europe, the Eurocode.

It’s generally accepted in the industry that the TIA code is the most easy to use. It was developed by the American Committee over many years and follows a straightforward, logical approach. The British Standard and Eurocode are similar but with more details – and complexity – than the TIA code. The Eurocode in particular is something of a mixed approach, as it includes national annexes through which individual countries specify their own requirements. That means that although Eurocode was developed in the early 2000s to unify building standards for Europe, it is in effect more a set of guidelines than hard-and-fast design rules for constructing towers.

A Sample Comparison of Codes

All three design codes specify varying methods of calculation, as well as approaches to making loading combinations, applying safety factors, etc. Comparing these methods, even briefly, can have revealing results. Of particular interest are the differences in the wind maps and topography categories. In all three codes wind maps are based on alternative parameters, namely:

| TIA Code | British Standard | Eurocode |

| 3-sec gust | Hourly mean | 10-min average |

To demonstrate the differences, we carried out some sample calculations according to Eurocode, with a wind speed of 30m/s. We then adjusted that figure to suit different codes according to wind speed conversions from TIA code:

| TIA Code | British Standard | Eurocode |

| 43.1 m/s | 28.6 m/s | 30m/s |

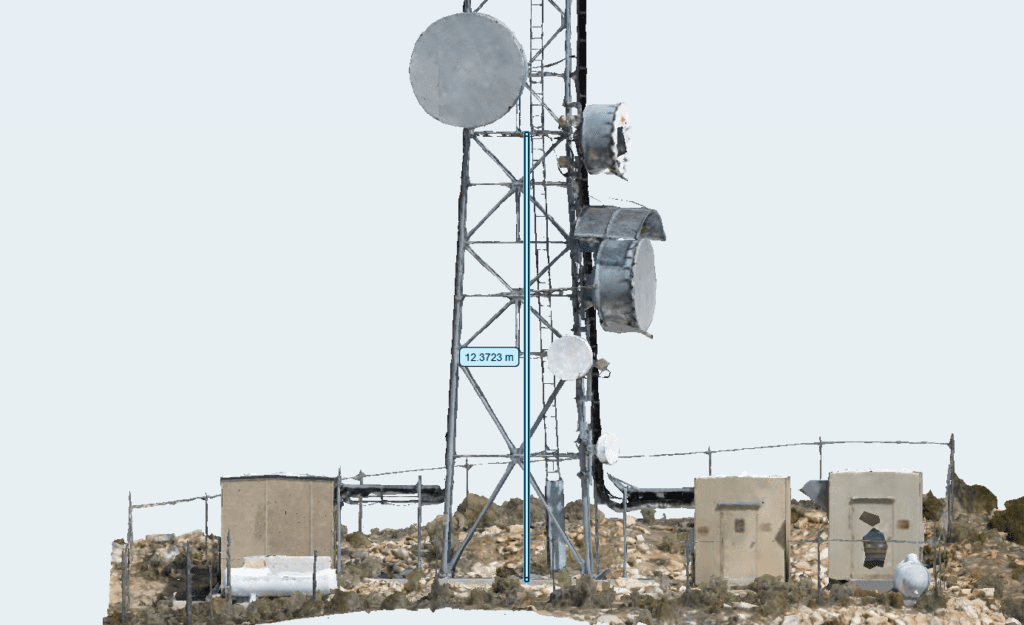

When the calculations were based on a tower in a flat area, the resulting difference between the codes was 15%. If, for example, a tower is placed on the top of a hill 200m high, the differences in the results are more striking – we’re seeing increases of more than 40% in some members.

More Analysis to Come

This is not unexpected, of course, as we’re dealing with different approaches to determining topography parameters, as well as other metrics. A more detailed comparative analysis would be worthwhile, but this paper demonstrates the value of even the quickest review: from the above calculations we can conclude that Eurocode generates the lowest stresses, with the British Standard in the middle, and the TIA code at the top end, causing the highest stress ratios in members.

For some service providers in our industry, these comparisons aren’t necessary, as they only operate within defined geographical borders. But for Delmec, it’s imperative that we not only have a strong understanding of individual codes, but also how they compare across the board. Many of our towerco clients will task us with designing, maintaining, managing and monitoring infrastructure across multiple territories. They know they can trust us to ensure that their towers and equipment are not just fully optimised, but safe too – for their team, their users and the communities in which they operate. At Delmec, Quality Control and Quality Assurance is not just a service we provide – it’s a way of life.